Benefits and Features of Impact Hurricane Windows

Hurricane Protection 101: Why Openings Matter and How This Guide Is Organized

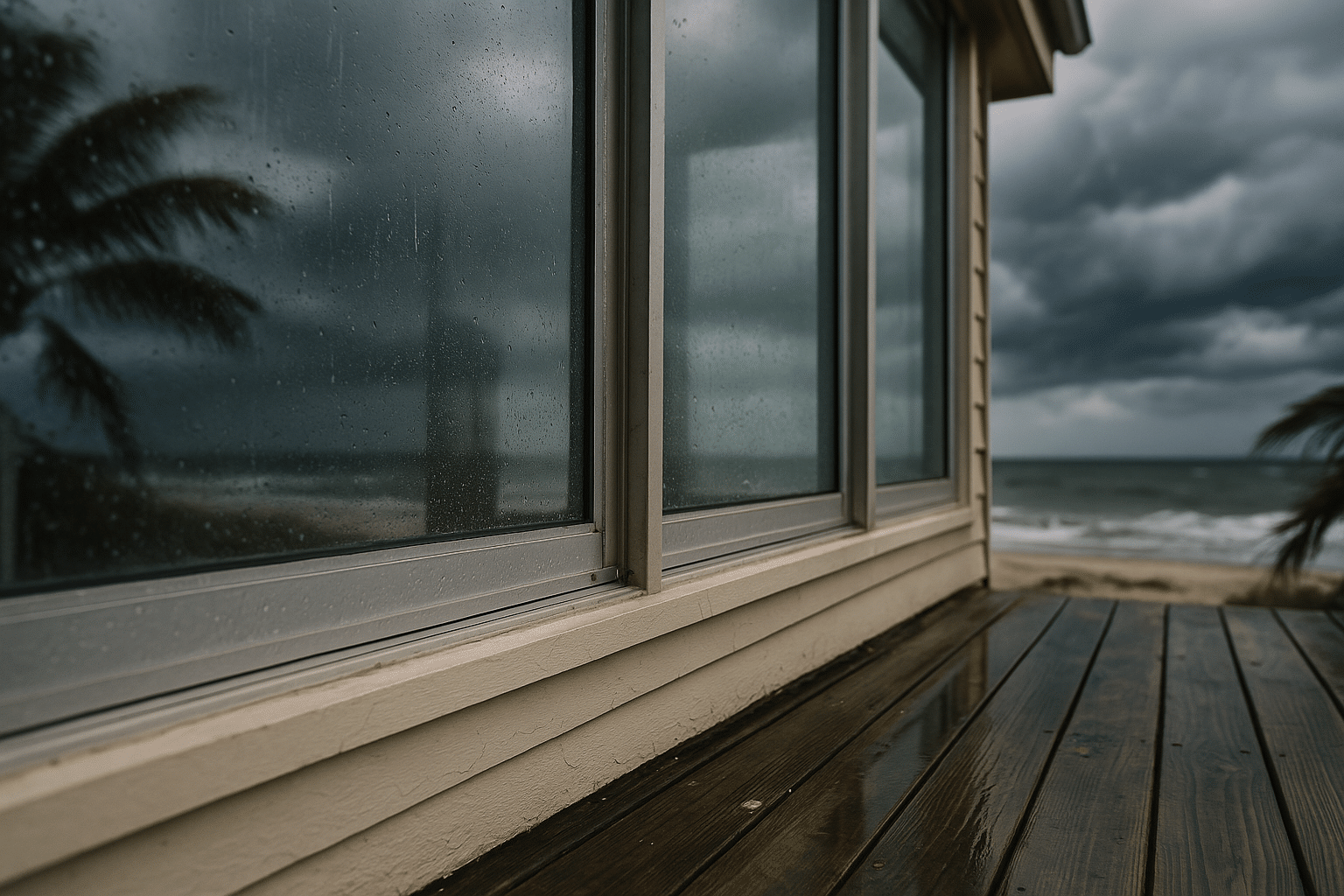

When the barometer drops and clouds turn the horizon the color of slate, the weakest part of a home reveals itself fast. A lost shingle is a nuisance; a failed window can be catastrophic. Broken glazing invites wind, rain, and pressure into the building, pushing upward on the roof and forcing water deep into walls. The goal of hurricane protection is simple: keep the building envelope intact by defending doors, skylights, and, especially, windows. This article lays out a practical playbook for impact glass and storm windows so you can choose a solution that fits your location, home design, and budget without guesswork.

Outline for this guide:

– Big picture: risk, codes, and why window failures cascade into larger damage

– Impact glass: how laminated panes, interlayers, frames, and seals work together

– Storm windows and shutters: types, deployment, visibility, and maintenance

– Costs and side benefits: money, comfort, noise, insurance, and resale

– Conclusion and next steps: selection, installation, and care checklist

Risk is not only about wind speed on a TV graphic; it is about debris, pressure cycling, and water entry. In lab testing, protective systems face impacts from a wooden projectile followed by thousands of positive and negative pressure cycles, a simulation of gusts and suction as a storm passes. In the field, the same physics apply: a palm frond or roof tile becomes a missile, striking glass before the pressure rollercoaster begins. If the opening holds, interior pressure stays closer to normal and the roof system has one less enemy. If the opening fails, repairs escalate from a sash replacement to drywall, flooring, and insulation throughout a floor. Codes in coastal regions reflect this chain reaction by requiring rated protection for glazed openings. Even where it is not mandated, a thoughtful plan that pairs impact-resistant glazing or storm windows with sound installation, proper fasteners, and reliable water management can turn a home from fragile to resilient. Think of it as choosing the right armor for the right battle, then fastening it correctly.

Inside Impact Glass: Construction, Testing, and Performance You Can Expect

Impact glass is laminated glazing designed to absorb blows without allowing a hole that compromises the envelope. The recipe is straightforward but carefully engineered: two or more sheets of glass bonded by a clear interlayer, commonly a polyvinyl or ionoplast film, with thicknesses that often range from roughly 0.76 mm to 1.52 mm. When struck, the glass may crack into a spiderweb, but the interlayer holds fragments together, resisting penetration. Frames, reinforcement, and anchoring are equally critical; a strong pane in a weak frame is like a shield held by a frayed strap.

Performance is verified through impact-and-cycling protocols (for example, E1886/E1996). A typical large-missile test launches a 9‑pound timber at about 34 mph into the glazing, followed by thousands of pressure cycles that simulate gusting winds from both directions. Products also carry design pressure ratings, expressed in pounds per square foot; common residential values might land in the ±35 to ±70 psf range, with taller buildings demanding higher numbers. These data points matter because they connect the product to your home’s exposure, height, and shape. When you match rating to reality, you get predictable resilience rather than hope.

Beyond storm protection, impact glass offers daily-life advantages. Laminated makeups block a large share of ultraviolet light, helping to reduce fading on floors and furnishings. With insulated configurations and low‑emissivity coatings, you can target comfortable U‑factors and solar heat gain values appropriate to your climate zone. Acoustically, laminated assemblies can deliver meaningful noise reduction; many homeowners report a calmer interior soundscape, with traffic and yard tools pushed to the background. Security improves as well, because the same resistance that slows a flying object also slows casual forced entry. Practical limits exist: glass can still crack, corner seals still age, and salty air is hard on hardware. Yet with correct selection and routine care, impact glazing provides a long service life that adds comfort every day and protection when it counts.

What to look for when comparing impact units:

– Verified impact and pressure cycling approvals appropriate to your region

– Clear documentation of design pressure ratings for your wind zone and building height

– Frames compatible with coastal conditions, with stainless or similarly corrosion‑resistant fasteners

– Drainage paths and sealant details that manage water as well as wind

– Glazing options that balance daylight, energy goals, and privacy

Storm Windows and Shutters: Where They Shine and Where They Don’t

Storm windows add a second protective layer to existing windows. They can mount on the exterior or interior and may use laminated glass, polycarbonate, or acrylic panels in aluminum, composite, or vinyl frames. Some are specifically impact‑rated; others are primarily weather shields that cut drafts and shed rain but are not designed to stop debris. Shutters and removable panels share the same objective—guard the opening—yet differ in permanence and convenience. Choosing between these options depends on how you live, how your home looks, and how quickly you want protection ready when forecasts turn urgent.

Consider the landscape of options:

– Removable corrugated panels (steel, aluminum, or clear polycarbonate) are budget‑friendly and store compactly; deployment takes time and labor.

– Accordion or hinged systems mount permanently and slide or swing into place; they deploy quickly but add visible lines to facades.

– Roll‑down units offer push‑button convenience and shade when partly lowered; they require professional installation and regular maintenance.

– Impact‑rated storm windows provide a clean look that stays up year‑round; they improve comfort and sound but may cost more than panels.

– Interior secondary panels can cut drafts and noise; unless impact‑rated, they should not be relied on as debris barriers.

Cost ranges vary by market and opening size, but ballpark figures help frame the decision. Removable panels might run around 8 to 15 currency units per square foot installed. Accordion systems often land near 20 to 35 per square foot, while roll‑downs can range from roughly 35 to 55. Impact‑rated storm windows frequently price near 45 to 90 per square foot, influenced by glass type, frame finish, and shapes like arches. These numbers reflect materials and labor; complex openings, multi‑story access, and corrosion‑resistant upgrades add cost. Performance differences mirror the form factor: permanent systems and impact‑rated storm windows offer faster deployment and better day‑to‑day convenience, while panels shine for pure affordability if you can store and install them quickly.

Tradeoffs matter. Panels can darken rooms and limit egress when installed; permanent shutters affect curb appeal; interior solutions preserve exteriors but may fog if not vented. Maintenance differs too: tracks and boxes on permanent units need cleaning and lubrication, while panels demand organized storage and labeled fasteners. The right choice is the one you will actually use on a stressful afternoon, not just the one that looks good on paper. If you want a set‑and‑forget approach, impact‑rated storm windows are appealing. If you need a lower initial outlay and can handle setup, panels remain a practical path. Many homes blend approaches, reserving quick‑deploy systems for large sliders or hardest‑hit elevations and using panels elsewhere.

Costs, Savings, and Side Benefits: Making the Numbers Work

Budget drives decisions, but cost alone rarely tells the whole story. Start with a simple exercise: count openings, note sizes, and list any shapes or second‑story locations that complicate labor. For a home with 12 average‑size windows at about 15 square feet each (roughly 180 square feet total), an installed impact‑glazing project priced at 70 per square foot would land near 12,600. Storm panels at 12 per square foot would be about 2,160. Accordion shutters at 28 per square foot would be around 5,040. Local labor, finishes, and corrosion‑resistant fasteners can nudge these up or down.

Savings come from several directions:

– Insurance: wind mitigation credits can reduce the wind portion of premiums when rated openings are verified; actual credits vary by carrier and documentation.

– Energy: insulated laminated units with appropriate coatings can trim cooling or heating loads; savings depend on climate, shading, and existing window condition.

– Comfort: acoustic damping yields quieter interiors; many households report better sleep and fewer interruptions from traffic or yard equipment.

– Security: resistance to quick entry can deter opportunistic intrusions, a benefit that is hard to price but easy to appreciate.

One way to think about value is to combine modest, realistic gains. Suppose your wind premium is 2,000 annually and verified protection earns a 15% credit on that portion; that would be 300 per year. If energy improvements and air‑sealing save 100 to 200 annually, and the quieter interior removes the need for a standalone noise treatment in a bedroom, the package begins to pay back in comfort even before you tally avoided storm damage. Payback is not guaranteed, and timelines vary; what you can aim for is a durable upgrade that performs daily and stands ready seasonally. Consider long‑term ownership costs too. Quality fasteners and coatings cost more upfront but resist coastal corrosion. Frameless looks might be tempting, but robust frames and proper sealants often outlast minimal profiles. A measured approach—clear scope, verified ratings, written warranties, and careful installation—turns the numbers in your favor without relying on rosy assumptions.

Conclusion and Next Steps: From Decision to Durable Comfort

Selection, installation, and care decide whether a hurricane protection plan performs on the day you need it. Begin by mapping your risk: exposure, nearby trees, roof height, and the orientation of big openings. Ask for product approvals that match your region’s wind and debris criteria, and verify design pressure ratings against your home’s height and shape. Insist on corrosion‑resistant fasteners and anchoring into structural members, not just sheathing. Good installers use back dams or sill pans, maintain weeps, and bed frames in sealants compatible with the materials in play. Gaps are shimmed and sealed thoughtfully, not stuffed with foam and forgotten.

A practical checklist:

– Confirm impact and pressure cycling approvals appropriate to your address; keep documents for insurance inspections.

– Match design pressures to site exposure and building height; higher floors often need higher ratings.

– Choose glazing packages for climate: low solar gain where cooling dominates, higher visible light where daylight matters most.

– Review egress and safety glazing requirements; bedrooms and near‑floor glass have rules to follow.

– Specify stainless or similarly resistant hardware and consider thicker coatings for coastal air.

– Plan deployment: if using panels, label each opening and fastener so you can install fast under stress.

– Schedule maintenance: wash tracks, clear weeps, lubricate moving parts, and inspect sealant yearly; re‑caulk as needed.

A few myths to drop now: tape on glass does not prevent shattering; slightly opening a window does not “relieve pressure”; and last‑minute shopping for panels rarely ends well. What does work is preparation married to a solution you can live with daily. Impact glass offers year‑round clarity, quieter rooms, UV filtering, and security with storm‑day strength. Storm windows and shutters deliver flexibility and, in many cases, lower initial cost. The right answer may be a hybrid that shields the largest or most wind‑facing openings with impact glazing while using panels elsewhere.

Closing thought for coastal and storm‑prone homeowners: resilience does not need to be loud or flashy. It looks like a window that shrugs at flying debris, a frame that drains and dries, and hardware that laughs at salt air. Build your plan now, verify the details, and your home will feel calm long before the radar lights up. That peace of mind is a form of comfort you notice every day, not just when the forecast turns gray.