Exploring Accredited Plumbing Schools and Programs

Outline:

– Why accreditation matters and how it protects students and the public

– Comparing program types: certificates, associate degrees, and apprenticeships

– Inside the curriculum: safety, codes, tools, and emerging technology

– Certification and licensing: exams, experience hours, and renewals

– Choosing a program: costs, aid, support services, and a practical decision checklist

Why Accreditation Matters in Plumbing Education

Accreditation is the quiet guardian of quality in trades education. For plumbing students, it confirms that a school or program has been reviewed by independent evaluators who check instructional rigor, facilities, student support, and outcomes. In a field where safety, water quality, and building integrity are at stake, that external validation is more than a seal—it’s a promise that training aligns with current codes and industry practice. Without it, you may face limited financial aid, tougher credit transfers, and employers who hesitate to recognize your coursework.

What does accreditation look at in practical terms? Reviewers examine lesson plans, lab setups, tool inventories, and the way instructors assess hands-on skills. They verify that safety is embedded from day one, not as an afterthought. They also assess data: completion rates, job placement metrics, and the availability of tutoring or career services. This oversight helps ensure students learn to size water supply lines, set proper drainage slopes, and solder or press joints with reliable technique—competencies tied directly to public health and building performance.

For students choosing between similarly priced schools, accreditation can be decisive. It often unlocks access to need-based aid and scholarships, which can reduce upfront costs for tuition, books, and tools. It also signals that the program is built to meet regional licensing requirements, helping you avoid repeating courses later. Consider these realities when you compare options:

– Quality assurance: Independent eyes verify instruction, labs, and outcomes

– Safety and code alignment: Curriculum maps to current standards and inspections

– Mobility: Credits and credentials are more transferable between institutions

– Employability: Employers frequently prefer candidates from vetted programs

In short, accredited plumbing education narrows the gap between classroom learning and real job sites. It reduces risk for you and for the communities you will eventually serve. While accreditation is not a guarantee of success, it is a reliable indicator that the program measures what matters and supports students on the path to licensure.

Program Paths Compared: Certificates, Associate Degrees, and Apprenticeships

Plumbing education offers several on-ramps, each with its own rhythm, cost, and career payoff. Certificate or diploma programs, typically running 6 to 12 months, focus on core skills: fundamentals of water distribution, drainage, venting, fixture installation, and entry-level code literacy. They are compact and job-oriented, a practical starting point for those eager to work quickly. Associate degree programs, usually 18 to 24 months, add general education, advanced math, blueprint analysis, estimating, and business fundamentals—useful for future supervisors or aspiring business owners. Apprenticeships blend paid employment with formal instruction over three to five years, allowing you to earn while you build competency under licensed professionals.

Each path suits different goals. If you want rapid entry into the field and can supplement classroom instruction with on-the-job learning, a certificate may be enough to launch an entry-level role. If you’re aiming for supervisory tracks or plan to manage projects later, an associate degree’s broader scope can help. Apprenticeships are compelling because they reduce financial pressure and expose you to real-world troubleshooting from day one. However, they require patience and commitment to a multi-year training schedule that includes evening or weekend classes.

When comparing, look beyond the brochure. Examine schedules (day, evening, weekend), lab-to-lecture ratios, and access to specialized equipment like pipe threading machines, press systems, or backflow testing rigs. Ask about partnerships with employers, which can mean priority for job interviews or structured work rotations. Consider these quick comparisons:

– Time: Certificates (6–12 months), Associate degrees (18–24 months), Apprenticeships (3–5 years)

– Cost: Classroom programs charge tuition; apprenticeships offset costs through wages

– Breadth: Degrees cover wider theory and soft skills; certificates emphasize core tasks

– Work immersion: Apprenticeships maximize supervised hands-on practice from the start

There is no single superior route. The right choice balances your timeline, finances, and learning style. Some students even stack credentials—starting with a certificate, then adding an apprenticeship or completing an associate degree once employed. Treat your path as a sequence, not a one-shot decision, and you’ll keep doors open as your goals evolve.

Inside the Curriculum: Safety, Codes, Tools, and Emerging Technology

Step into a well-run plumbing lab and you’ll hear the chorus of cutters, torches, and testers alongside careful explanations of why each step matters. Early courses build a foundation in safety—personal protective equipment, lockout procedures, ladder use, and hazard recognition—because one lapse can damage systems or injure people. From there, students learn the physics of water, pressure, and flow. You’ll size supply lines, calculate drainage slopes, and map venting paths that keep fixtures operating quietly and reliably. Code literacy is woven through every module so that what you practice in the lab matches what inspectors expect on site.

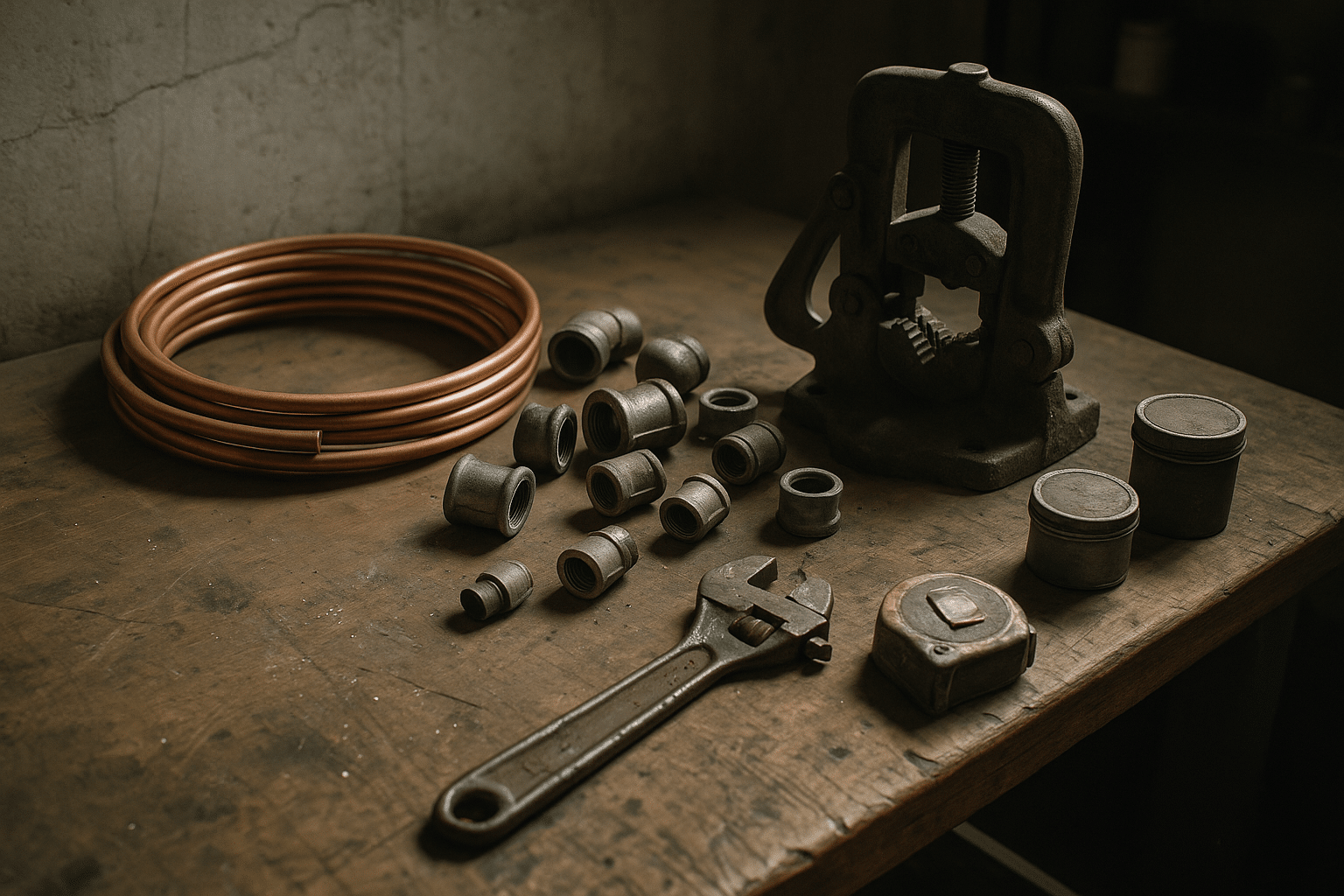

Tool competency is another major theme. Students master measurement and layout, cutting and joining methods for copper, steel, and plastics, and the operation of threading machines and pressing tools. Leak testing, backflow prevention, and fixture setting become second nature. Instructors emphasize troubleshooting: diagnosing low pressure, uneven temperatures, sewer gas odors, or intermittent leaks without tearing apart finished walls. You’ll learn to sequence tasks efficiently, coordinate with other trades, and document work for permits and inspections.

Modern programs also address technology and sustainability. Expect modules on high-efficiency fixtures, recirculation strategies, water quality testing, and cross-connection control. Digital elements are increasingly common: reading plans on tablets, capturing photos for inspection records, and using simple diagnostic sensors to confirm performance. Residential and commercial differences are highlighted so you can shift from a kitchen remodel to a multi-story riser without missing critical details. Common curriculum components include:

– Safety and risk control integrated with practical labs

– Codes and standards interpretation with real plan sets

– Piping materials and joining methods across metals and plastics

– Drainage, waste, vent, and water supply design principles

– Backflow prevention and cross-connection control fundamentals

– Troubleshooting workflows and documentation techniques

– Introductory business skills: estimating, customer communication, scheduling

By the time you complete an accredited program, you should be able to translate a set of drawings into a complete installation plan, defend your choices with code references, and test your system with confidence. That’s the bridge from classroom exercises to jobsite reliability.

Certification and Licensing: From Trainee to Master

Licensing and certification convert your training into recognized authority. While exact requirements vary by state or region, the progression typically follows a path from trainee or apprentice to journeyman and, after additional experience and exams, to master level. Each step combines classroom hours, documented job experience, and a proctored test designed to measure safety, code knowledge, and problem-solving under time pressure.

The journeyman phase often requires several thousand hours of verified field work plus formal instruction. Exams prioritize practical interpretation: calculating pipe sizes, reading isometric drawings, identifying acceptable materials and joint methods, and applying rules for venting, trap arms, and cleanouts. Some jurisdictions add specialty endorsements—gas fitting, medical gas, or backflow testing—that require separate study and assessments. Maintaining clear records of hours, projects, and supervisor signatures makes application and renewal smoother.

Preparation strategies are straightforward but disciplined. Work through code sections in small, daily sessions, using tabs or indexes to find answers quickly. Practice sample questions that mimic exam timing so you’re comfortable navigating references under a clock. Build a formula sheet for common calculations, and rehearse steps for procedures like pressure testing. During your apprentice years, ask to rotate through varied tasks—rough-ins, trim-outs, service calls—so your experience matches the exam’s breadth. Consider these steps:

– Verify your jurisdiction’s hours, coursework, and documentation rules

– Register early for exam dates and study consistently in short intervals

– Simulate test conditions with timed, open-book practice

– Pursue add-on endorsements to expand your scope and employability

– Track continuing education for renewals and code cycle changes

Licensure is not merely paperwork; it’s a public trust. Communities rely on licensed plumbers to protect drinking water, vent hazardous gases safely, and ensure that systems perform under daily stress. Treat every credential as an agreement to uphold that trust through ongoing learning and careful workmanship.

Choosing a Program and Your Next Steps: A Practical Conclusion

Selecting an accredited plumbing program is part research, part intuition, and part logistics. Start with clear goals: Are you aiming for rapid entry via a certificate, a broader associate degree, or an earn-while-you-learn apprenticeship? Then map your finances. Factor in tuition, fees, books, basic tools, and commuting. Apprenticeships offset costs with wages, but classroom programs may offer grants, need-based aid, or work-study that ease the burden. Ask the financial aid office to outline total cost of attendance—not just tuition—so you can compare options on equal footing.

Visit campuses and training centers. A productive lab shows signs of real use: scuffed benches, organized tool walls, mockups that reflect current materials, and clearly posted safety procedures. Observe class size and instructor availability, because low student-to-instructor ratios boost feedback during hands-on tasks. Request recent data on completion and job placement; strong programs track outcomes and connect students with local contractors for internships or first jobs. Alumni panels or open shops can reveal how well the curriculum translates to field demands.

Use a simple checklist to finalize your decision:

– Accreditation confirmed and aligned with your region’s licensing path

– Transparent costs, tool lists, and realistic schedules for work-life balance

– Robust labs with current materials and assessment rubrics

– Employer connections, mock interviews, and resume or portfolio support

– Tutoring, exam prep, and continuing education opportunities

As you move forward, think in phases. Phase one is foundation: safety, codes, core skills. Phase two is application: supervised work, troubleshooting, and exam prep. Phase three is growth: endorsements, leadership, and project planning. With that roadmap, you can choose a program that respects your time and resources while preparing you for the responsibilities of safeguarding water and sanitation. The trades reward steady effort; take the next step with a clear plan and the confidence that accredited training will help you turn skill into a lasting career.