Benefits and Design Options for Stamped Concrete Patios

Outline

– Section 1: Decorative Concrete 101—how stamped slabs are made, what they do well, and common misconceptions.

– Section 2: Benefits and trade-offs—cost ranges, durability, safety, and maintenance realities.

– Section 3: Design options—patterns, colors, borders, scaling, and drainage details that affect performance.

– Section 4: Outdoor living integration—zoning, furniture clearances, shade, lighting, and comfort strategies.

– Section 5: Installation, maintenance, sustainability, and a practical conclusion for planning your project.

Decorative Concrete 101: What Stamped Concrete Really Is

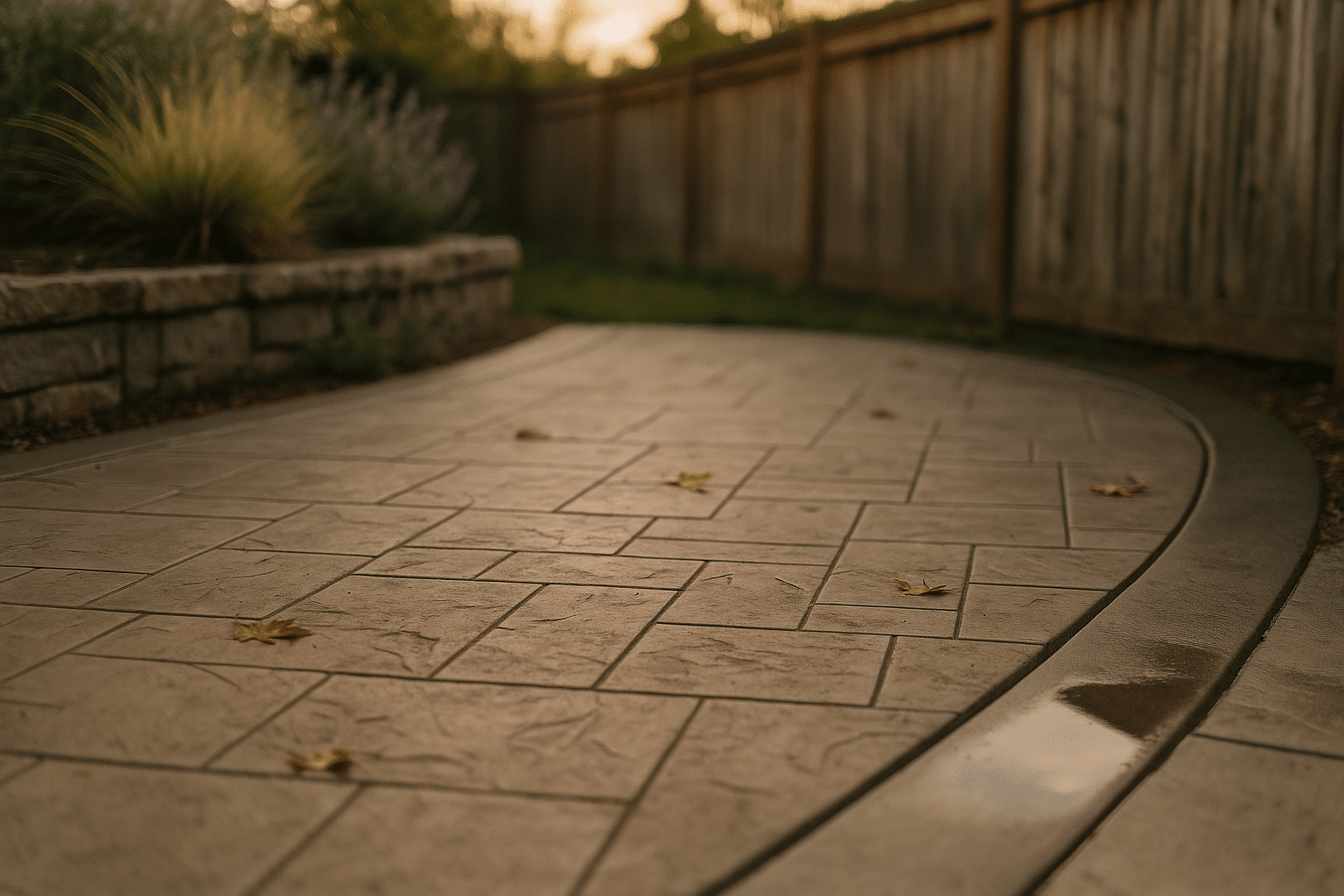

Stamped concrete is standard concrete upgraded with color and texture to echo the look of natural materials—think stone, brick, tile, or wood—while keeping the monolithic strength of a single slab. At its core, concrete is a mix of cement, sand, aggregate, and water, commonly proportioned to achieve compressive strengths around 3,000–4,000 psi for residential flatwork. The decorative magic happens during a narrow work window: fresh concrete is colored (integrally or at the surface), a powdered or liquid release is applied, and rigid or flexible stamping mats imprint a pattern as finishers work across the slab. Control joints are cut or tooled to manage shrinkage cracks, ideally aligned with the pattern so they vanish into faux “grout lines.” After curing, a sealer protects color and adds a selected sheen—matte for a subdued, stone-like vibe or a soft gloss for subtle highlights.

Because the slab is continuous, stamped patios resist weed growth between joints and shifting units, issues sometimes seen with segmental pavers. That same monolithic nature means repairs require skill to blend colors and textures if a localized patch is needed. Slip resistance is engineered through texture depth, release selection, and additive grit in sealers; with the right finish, feet feel secure even when a mist settles after a summer watering. In freeze–thaw regions, air-entrained mixes and proper curing are important to improve resistance to scaling from deicing salts. Expansion and isolation joints accommodate movement at foundations, steps, and utility pads, reducing stress on the decorative field.

Common misconceptions deserve a quick reset. Stamped concrete is not fragile; with adequate base prep, proper thickness (often 4 inches for patios, more at load points), and reinforcement (fibers, wire mesh, or rebar as specified), it stands up to decades of use. Nor is it a one-look finish: modern color systems, texture skins, and custom borders create thousands of combinations, from rustic slate to clean, large-format tile appearances. As a rule of thumb, careful subgrade compaction and drainage planning do more for long-term performance than any single finishing choice.

- Typical compressive strength: ~3,000–4,000 psi for residential slabs.

- Recommended patio thickness: commonly 4 inches; local conditions may warrant more.

- Slope for drainage: about 1–2% (roughly 1/8 to 1/4 inch per foot) away from structures.

Benefits and Trade-offs: Cost, Longevity, Safety, and Maintenance

Stamped concrete often appeals to homeowners because it delivers an elevated appearance without the higher labor of setting individual stones. In many U.S. markets, installed costs for stamped patios commonly fall in a middle range compared with other hardscapes. While pricing varies by region, access, pattern complexity, and finish, broad estimates can be summarized for planning purposes. Consider them directional, not prescriptive; local quotes will refine the numbers.

- Stamped concrete patio (installed): roughly the mid-teens to mid-twenties per square foot for typical residential work, with basic designs at the lower end and elaborate borders or multicolor finishes at the higher end.

- Segmental pavers: often the mid-teens to mid-thirties per square foot depending on base depth, pattern, and edge restraints.

- Natural stone laid on concrete: can range widely, often starting in the twenties and extending higher with premium materials and complex layouts.

- Wood or composite deck: frequently comparable to or higher than decorative concrete when accounting for substructure and railings.

Beyond initial cost, ownership value shows up in durability and upkeep. A well-placed stamped slab can serve 25–40 years or more with periodic care. Routine maintenance is modest: rinse as needed, wash with a pH-neutral cleaner, and reseal every 2–3 years in sunny climates or 3–5 years in milder zones. Resealing helps preserve color, boosts stain resistance, and refreshes texture definition. For traction, a fine polymer grit can be added to sealers, producing a comfortable, slip-resistant surface. Where snow and ice are common, shoveling with a plastic blade and using sand rather than harsh deicers helps minimize surface scaling. If a crack does appear, pro finishers can disguise it as a “natural” joint or incorporate a sawcut to re-balance the stress and tidy the look.

Trade-offs are real and manageable. Because a stamped patio is monolithic, below-slab utilities should be planned in advance, with sleeves for irrigation or lighting runs to avoid future cuts. Repairs must be color-matched with care; while achievable, they are more involved than swapping a single paver. Thermal comfort varies by color—lighter tones reflect more sunlight and stay cooler underfoot, helpful in hot climates. In shaded or damp microclimates, a breathable, high-quality sealer selection supports vapor transmission and reduces whitening (blushing). Taken together, stamped concrete offers an appealing blend of cost control, longevity, and visual range for many outdoor living goals.

Design Options: Patterns, Colors, Borders, and Details That Matter

The design palette for stamped concrete is broad, spanning classic masonry cues to contemporary geometry. Pattern selection does more than set a mood; it influences how joints, borders, and furniture read at full scale. Large ashlar layouts can make small spaces feel expansive, while tighter cobble or running-bond patterns add rhythm that complements cottage gardens. Wood-plank stamps bring a warm, tactile look to coastal or cabin themes without the upkeep of actual timber. Texture skins—subtle slate or sandstone finishes—give a refined tone when you want fewer grout lines and a calmer visual field.

- Popular patterns: ashlar slate, flagstone, cobblestone, herringbone brick, fan, large-format tile, and wood plank.

- Color systems: integral color for through-body hue, dry-shake hardeners for a denser, more saturated surface, and stains (water-based or reactive) for nuanced accents.

- Antiquing effects: release powders or liquids settle in low points, adding shadow for realism.

Borders and banding frame the patio like trim on a well-made suit. A contrasting soldier course, a smooth ribbon against a textured field, or a color shift at steps and landings improves both aesthetics and safety. Joint planning is equally practical: align sawcuts with faux grout lines so movement control is hidden in plain sight. Scaling matters—oversized patterns can look striking on large terraces but feel busy on compact footprints. To help visualize, lay out furniture footprints with tape or cardboard and “walk” the space before pouring; this prevents a dining chair leg from landing on an awkward groove.

Performance hinges on details. Maintain a consistent slope of 1–2% for drainage, directing water away from structures and planting beds that dislike wet feet. Consider heat: pale grays, sands, and light buffs stay cooler in sun, while deeper charcoals and chocolates excel in shade or shoulder seasons. For edges, bullnose treatments soften step fronts, and textured nosings add traction. Steps typically feel comfortable with 6–7 inch risers and ~11 inch treads, and integrated seat walls often sit nicely between 18–22 inches high. When in doubt, build a small mockup board with final colors and textures; sunlight at 8 a.m. tells a different story than at 5 p.m., and the right sample makes the decision clear.

Outdoor Living Integration: Zoning, Comfort, and Nighttime Ambience

A great patio is not just a surface—it is a small neighborhood of activities that flow together. Start by zoning: dining, cooking, lounging, and circulation should each have a defined footprint that still feels connected. For a table seating six, a useful rule is to allow a zone roughly 10 by 12 feet, providing 36–48 inches of clearance around chairs for easy pull-back and passage. Grilling or outdoor cooking areas benefit from noncombustible surroundings, cross-ventilation, and a landing zone for trays. Lounging clusters feel relaxed with a 3-foot path skirting the furniture and a coffee table spacing of 18 inches from seating edges.

- Circulation: keep primary walkways at 36–48 inches wide; two people can pass comfortably at 48 inches.

- Shade: combine living shade (trees, vines) with built elements (pergolas, umbrellas) to track the sun from spring through autumn.

- Wind and privacy: low seat walls, planters, or lattice screens calm breezes and shape views without feeling closed in.

Comfort is multi-sensory. Underfoot texture matters—choose a stamp that is gentle for bare feet yet grippy when wet. Above, dappled shade encourages lingering; deciduous trees provide sun in winter and coolness in summer. Sound can soften edges too: a small bubbler near a garden bed or rustling ornamental grasses mask street noise. Lighting ties the evening together. Low-voltage path lights define routes without glare, while recessed step lights and downlighting from structures create layers. Aim for warm color temperatures for a welcoming tone, and position fixtures to graze the stamped texture—subtle shadows reveal the pattern’s relief in a way that feels natural, not staged.

Utility planning keeps things tidy. Add conduit sleeves beneath the slab before the pour for future power or speaker runs. Provide hose bibs and irrigation valves where planters will thrive, and keep storage for cushions or firewood nearby. If a fire feature is on your wish list, locate it with clearances from seating and structures, and choose complementary finishes so the hearth reads as part of the composition. The result is a patio that behaves like an outdoor room: coherent, comfortable, and ready for everyday rituals, from sunrise coffee to late-night stargazing.

Installation, Maintenance, Sustainability—and a Practical Conclusion

Successful stamped concrete projects follow a disciplined process. Site preparation starts with removing organic material and establishing subgrade at the correct slope. A compacted base—often 4–6 inches of well-graded aggregate for patios—supports the slab and improves drainage. Forms set the geometry, and reinforcement (fibers plus wire mesh or rebar where appropriate) helps control crack behavior. Placing and finishing teams coordinate timing so coloring, release application, and stamping occur while the concrete is in the right plastic state. Once the pattern is set and joints are placed, the slab cures; concrete gains most of its strength within a week and approaches design strength around 28 days. Sealer follows after adequate dry time, with careful weather checks to avoid trapping moisture.

- Control joint spacing: commonly 2–3 times slab thickness in feet (for a 4-inch slab, joints about 8–12 feet apart), adjusted for pattern and geometry.

- Reseal cadence: every 2–3 years in sunny, high-traffic areas; 3–5 years in milder conditions.

- Winter care: avoid aggressive deicers the first season; use sand for traction and rinse residues in spring.

From a sustainability lens, a long-lived slab reduces material turnover and transport impacts. Light-colored mixes can improve solar reflectance, moderating surface temperatures around planting beds. Locally sourced aggregates, mindful water curing, and efficient logistics also contribute to a gentler footprint. For stormwater, pair a stamped patio with permeable borders, planting strips, or subsurface drains to manage runoff responsibly. When comparing life-cycle costs, factor in not only the first price but also the years of service, resealing intervals, and any anticipated repairs.

Conclusion for homeowners: define goals first, then let them steer design and budget. Sketch your zones, measure clearances, and collect two or three pattern-color combinations that support how you live—quiet mornings, family dinners, or larger gatherings. Request written scopes that detail subgrade prep, thickness, reinforcement, joint layout, and sealer type; clarity up front prevents surprises later. Ask to see physical samples in your yard’s light, morning and late day. Finally, plan for care: a gentle wash, an occasional reseal, and seasonal commonsense keep the surface looking fresh. With a thoughtful process, stamped concrete becomes a hardworking stage for your outdoor life—durable, adaptable, and styled to your taste without demanding daily attention.