Practices for Effective Gutter Guard Installation

Outline and Why Gutter Protection Matters

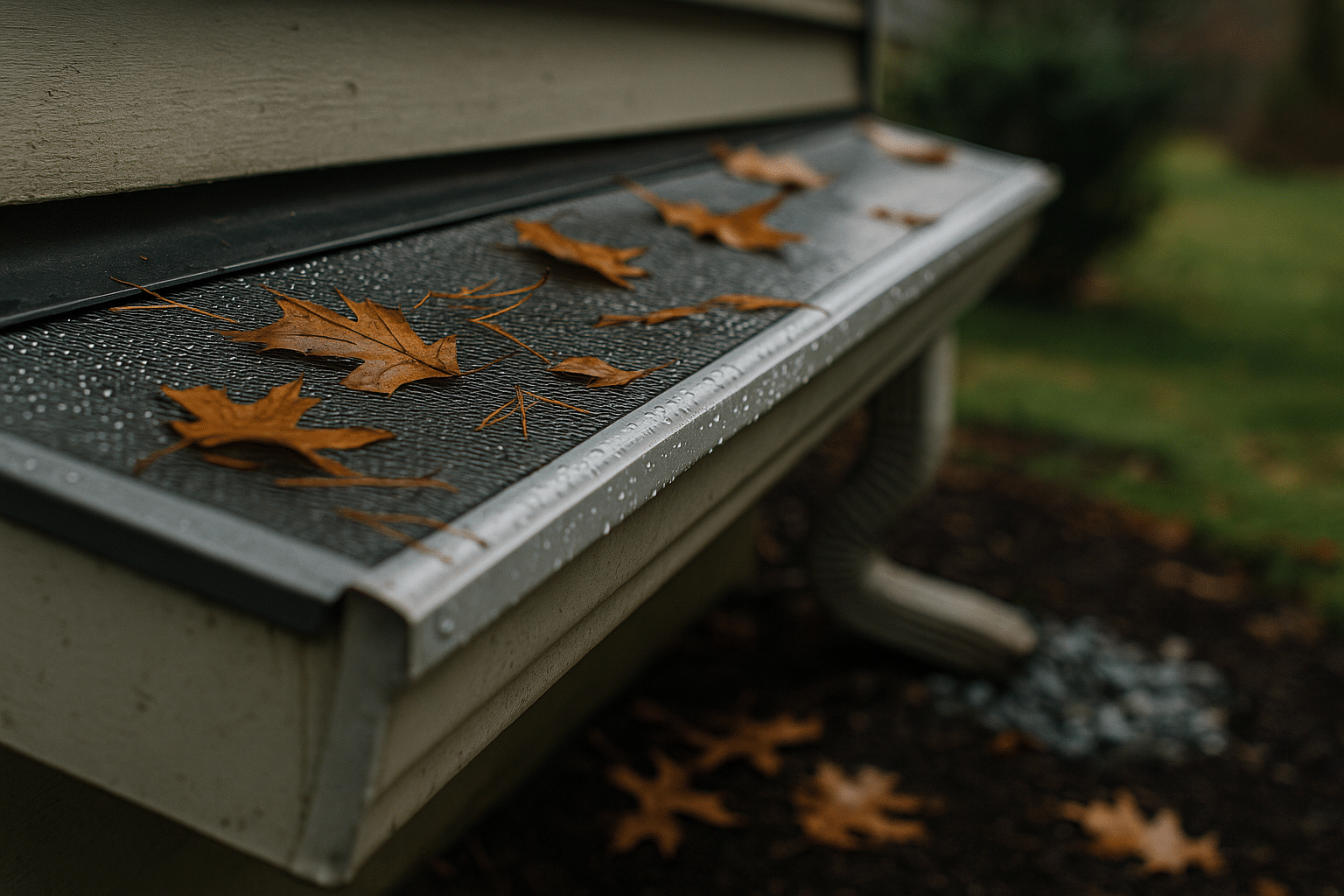

Gutters are small components that do big work, channeling stormwater away from vulnerable edges and foundations. When they clog, water cascades over the lip, saturates soil, and can creep into basements or crawlspaces. Overflow also streaks siding, rots fascia, and accelerates freeze–thaw damage. A straightforward way to reduce all of that is to pair clean, pitched gutters with leaf guards that filter debris and keep flow paths open. The goal is not just tidy eaves; it’s a reliable water management system that stands up to heavy downpours and seasonal leaf drops. For perspective, 1 inch of rain on a 1,000-square-foot roof sends about 623 gallons of water toward your gutters, and that must go somewhere predictable.

This article follows a practical roadmap—first an overview of gutters as a system, then a comparison of guard designs, next installation techniques, and finally how to direct water safely on the ground. Here’s the outline you’ll see unfold, with maintenance woven throughout:

– Fundamentals: gutter anatomy, flow dynamics, materials, profiles, and sizing principles.

– Leaf guards compared: screens, micro-mesh, foam, brush, and reverse-curve performance in real conditions.

– Installation practices: assessment, pitch, fastening, sealing, and climate-specific notes.

– Rainwater management: downspout sizing, dispersion, harvesting, and erosion control.

Think of your roof as a compact watershed. Wind delivers leaves, needles, and grit to the gutter apron. Sun bakes them into a thatch, and the next storm turns that thatch into a dam. Leaf guards act like a gentle bouncer at the club door—most debris is turned away, water gets in, and you spend less time cleaning ladders and more time staying safely on the ground. None of this removes maintenance entirely, but it stretches the interval between cleanings and improves performance during those intense, short-lived cloudbursts that test every seam and fastener.

Gutter Protection Fundamentals: Materials, Profiles, and Flow

A dependable system starts with sound gutters before you even consider guards. Materials vary in strength, corrosion resistance, and appearance. Common choices include aluminum for a light, rust-resistant channel; galvanized steel for rigidity with proper coating care; copper for longevity and patina; and vinyl for budget-friendly installs in mild climates. Profile matters too: K-style gutters carry more water per inch of width thanks to their broad back and angled front, while half-round profiles shed debris well and suit traditional aesthetics. Typical residential sizes are 5-inch K-style or half-round, with 6-inch options offering increased capacity for larger roofs or high-intensity rainfall regions.

Flow depends on a few simple physics ideas. Water follows the path of least resistance, aided by pitch and surface tension. Proper slope is modest: about 1/16 to 1/8 inch per foot. Too little pitch, and water lingers with sediment; too much, and you invite noisy flow and potential overshoot at outlets. Hangers should be spaced roughly every 24 to 32 inches, closer in snowy or windy locations, to prevent sag that creates standing pools. Seal every seam and end cap with compatible, durable sealant, and ensure a clean, continuous bed beneath the gutter to avoid ripples that trap debris. Where roof shingles terminate, a drip edge or compatible flashing prevents capillary action from sending water behind the gutter.

Guards interact with these fundamentals. Even an outstanding guard can’t fix a mis-pitched trough or under-sized downspouts. Evaluate the roof area—multiply length by projected run to estimate square footage—and pair it with typical storm intensity for your area. As a rule of thumb, 1 inch of rain equals 0.623 gallons per square foot. That simple figure helps you visualize loading on long runs and whether you should step up to larger gutters or additional downspout drops. The result you’re after is predictable capture: no frequent overtopping at inside corners, no rotor wash of water past entry points, and clean transitions into downspout outlets sized to the task.

Some practical cues help before you touch a guard: look for tiger-striping (dark vertical streaks) that suggests prior overflow, check fascia for softness, and inspect the first and last ten feet of each run—these are common failure zones. Debris patterns tell stories: broad leaves clump and mat; pine needles stitch into dense filters; seed pods wedge into outlets. Knowing what lands on your roof informs the guard style you’ll likely choose next.

Leaf Guards Compared: Screens, Micro-Mesh, Foam, Brush, and Reverse-Curve

Leaf guards share a purpose—keep debris out and let water in—but they achieve it differently, and each design suits certain roofs, trees, and climates.

Screens use perforated metal or rigid polymer with holes sized to block larger debris. They are simple to install, relatively light, and friendly to periodic DIY cleaning. With broadleaf trees, screens perform well because they shed dry leaves. In storms with high rainfall rates, the open area admits water readily, but finer debris like shingle grit and small seeds can pass through or lodge in holes. Choose heavier-gauge, corrosion-resistant screens if snow loads or coastal air are factors, and ensure they sit flat to prevent wind lift.

Micro-mesh systems filter down to very small particles, often in the tens of microns, using fine stainless mesh bonded to a support frame. They are well-regarded for blocking pine needles and grit while still pulling water by surface tension. On steep roofs or during intense cloudbursts, quality micro-mesh can still keep up if pitch and alignment are correct, because the water film adheres and transitions into the gutter. In freezing climates, however, any guard with fine texture can hold a skim of ice; adequate attic ventilation and periodic checks help mitigate that risk.

Foam inserts fit inside the gutter, filling the void so water passes through pores and debris tends to dry and blow away. Their advantages include quick installation and compatibility with many gutter profiles. Over time, UV exposure, organic growth, and sediment can reduce porosity, so expect more frequent service in humid or heavily shaded settings. Brush inserts rely on upright bristles that hold debris above the flow path. They resist crushing and are easy to remove for cleaning, but fine needles can tangle in bristles, gradually forming a mat that needs occasional combing out.

Reverse-curve (surface tension) guards cap the gutter with a curved nose that rolls rain into a slot while leaves slide off the edge. When dialed in, they handle heavy rain smoothly and shed larger debris neatly. Sensitivity to installation is higher: if the nose is misaligned with the drip line, fast water can overshoot. In areas dominated by small, flexible debris, some particles can ride with the water into the slot. For metal roofs with rapid snow slides, ensure a compatible snow retention strategy so sheets of ice don’t impact the guard lip.

Choosing among these options is about matching debris type, climate, and maintenance appetite. Quick guide notes you can apply:

– Large leaves and moderate storms: perforated screens or reverse-curve often shine.

– Pine needles and shingle grit: micro-mesh offers exceptional exclusion.

– Budget and easy removal: foam or brush inserts keep things simple.

– Steep pitches and high flow: sturdy screens or well-aligned micro-mesh with strong support frames.

No design eliminates maintenance entirely; the right pick reduces frequency and makes service safer and faster. Check access points near downspouts and inside corners—the places most likely to need a seasonal sweep.

Installation Practices: Assessment, Pitch, Fastening, and Climate Smarts

Good installations start on the ground with a plan, not on the ladder with a guess. Walk the perimeter and note roof planes, valleys, and points where two flows converge. Identify tree species overhead and how winds move around the structure—prevailing winds often explain where debris accumulates. Measure runs, verify the existing slope with a level, and mark any sections with ponding. If gutters are dented or fasteners are backing out, address structure first; guards can’t compensate for sag or rot.

Prepare by cleaning each run thoroughly. Flush with water after debris removal to confirm smooth, continuous flow to outlets. Seal seams and ensure ferrules or hidden hangers are tight and consistent. When adjusting slope, aim for 1/16 to 1/8 inch per foot, and avoid dramatic pitch changes mid-run. Add or enlarge outlets where needed, and consider upsizing downspouts at long valleys that concentrate flow. Fasteners matter: use corrosion-resistant screws compatible with the gutter metal to avoid galvanic reactions. Keep penetrations above the waterline where possible, and avoid placing screws where they can trap debris.

Guard alignment is the performance hinge. For screens and micro-mesh, set panels to match the roof’s edge and create a continuous plane that discourages debris catch points. Overlap joints per the manufacturer’s guidance, and ensure corners are reinforced, as turbulence at inside corners is where most overflows begin. For reverse-curve guards, the nose should sit within the drip path so water clings and turns into the slot; minor adjustments make major differences, so test with a hose before finalizing. Foam and brush inserts should be snug without compressing into an oval—uniform contact along the length prevents bypass gaps.

Climate tweaks pay off. In snowy regions, reduce the chance of ice dam interaction by ensuring soffit ventilation is adequate and by keeping guards flush to the roof plane. In coastal air or industrial pollution zones, prioritize stainless or well-coated materials and rinse guards during seasonal maintenance to reduce corrosive buildup. In wildfire-prone areas, avoid guards with large plastic surfaces and consider fine metal mesh that reduces ember intrusion while maintaining airflow. Always cap sharp edges, wear eye protection, and use stable ladder footing; safer work is smarter work, and rushed installs lead to callbacks.

Before you call it done, test everything. Simulate a storm with a garden hose, starting gently and ramping up to mimic a summer downpour. Watch corners, outlets, and any long straight sections where surface tension can pull water past the lip. Final checks you should never skip:

– Confirm pitch with water flowing—no lingering pools after flow stops.

– Ensure downspouts run clear and discharge at least several feet from the foundation.

– Verify all guard seams, overlaps, and terminations lie flat with no lift points.

– Photograph key areas for future reference and maintenance planning.

Rainwater Management Strategies and Conclusion

Once water enters the gutter, the next mission is to move it to a safe destination. Right-sizing downspouts protects against bottlenecks. A common 2-by-3-inch downspout can serve many small roofs in moderate climates, but larger roofs, inside valleys, or regions with high rainfall intensity benefit from 3-by-4-inch channels or multiple outlets. A quick sizing approach: Area (square feet) × Storm depth (inches) × 0.623 = gallons to convey. If a 1,400-square-foot catchment sees a 1-inch event, about 872 gallons are in play. Spread that across two or three downspouts, and the flow per outlet becomes manageable, especially when a corner also captures a valley.

At grade, choose a strategy that fits your site. Splash blocks and rigid extensions push water beyond the backfill zone. Corrugated pipe can route flow to daylight on a slope, while a simple gravel trench disperses smaller volumes into soil. Where clay dominates or basements are deep, dry wells or infiltration chambers absorb runoff in a controlled pocket. For landscapes that enjoy periodic wet feet, a rain garden captures bursts, slows flow, and filters sediment through layered soils. The theme is the same: create predictable pathways and buy time for water to soak or move without eroding mulch beds or undermining patios.

Harvesting is a smart bonus. Rain barrels or cisterns coupled with first-flush diverters reduce roof grit and pollen loading in storage. Leaf guards upstream reduce maintenance on filters and keep barrel screens clearer longer. Add an overflow routed to the same safe discharge path you’d use without storage, because every tank fills eventually. Practical details that pay off include dark-colored, opaque tanks to limit algae, screened inlets to deter mosquitoes, and shutoffs that are easy to reach from the ground.

Maintenance keeps the whole system honest. Even with guards, plan seasonal inspections—after leaf drop and after spring pollen. Focus on inside corners, downspout drops, and any roof edge shaded by overhanging limbs. Light sweeping at the guard surface is usually all that’s needed. Quick checklist for ongoing care:

– Trim branches that feed heavy debris directly above valleys and eaves.

– Re-level sections that show new sag or nail pop, especially after ice or wind events.

– Flush downspouts yearly and re-seat extensions that wander during landscaping.

Conclusion: For homeowners and building managers aiming for dry basements, clean lines, and low drama in heavy weather, a well-chosen guard paired with right-sized downspouts and smart ground discharge is a dependable, long-term play. Match the guard to your debris, tune the pitch, test with a hose, and give water an easy route to leave the site. Do that, and you’ll trade emergency ladder climbs for quick seasonal checkups—and your foundation, fascia, and plantings will quietly thank you every storm.